TC-V Elastic vibrating hammer is a patent product of advanced and efficient ash removal series developed by Changsha Tianwei Huaxin Environmental Protection Equipment Co., Ltd. on the basis of absorbing advanced technology at home and abroad and combining practical experience of operation. It can remove all kinds of dust adhering on the equipment and is an efficient dust removal tool.

Compared with other similar products at home and abroad, many new processes and technologies have been adopted, as follows:

The non-stress tension spring is adopted. Patent Number: 201721633056.6

A Force Regulation Device which can adjus the force infinitely, Patent Number. 201821932138.5

A Vibrating bar which no need to replace, Patent Number: 201821931778.4

Ordinary spring

The non-stress tension spring

A Force Regulation Device which can adjus the force infinitely

Compared with similar products, the following four problems have been successfully solved:

1. It is difficult to adjust the force and cant adjust the speed infinitely, especially when it is in use.

2. The tension spring hook is easy to break.

3. When the vibrating rod is replaced with the disc spring, the vibrating rod should be replaced as a whole.

4. The motor is easily stuck and burnt.

TC-V has become more advanced and reliable elastic hammer .

Product use

TC series elastic vibration hammer can be used for ash cleaning of various boilers, pipes and silos.

Product characteristics

Vibration force can be adjusted in the range of 40-400 kN, which saves a lot of time for users.

Patented spring, hook for 2 years.

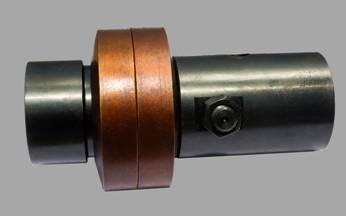

Patented vibrating rod, no need to replace the vibrating rod when disassembling, assembling and replacing the small disc spring.

High reliability and trouble-free operation.

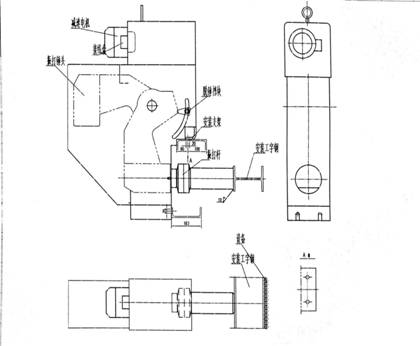

Structural principle

The motor drives the active sprocket through the worm wheel and worm reducer, then drives the driven sprocket through the chain, and the driven sprocket drives the lifting hammer device. After lifting the hammer head to the set height, under the action of the drop hammer device, the hammer head drops to strike the spring vibrating rod. The hammer lifting mechanism continues to rotate with the driven wheel, through the guide reset, lifts the hammer again, and carries on the second vibration, so that the cycle starts again and again.

A pair of disc springs are installed on the spring vibrating rod, which makes the vibrating force vibrate at a specific frequency and transmit to the ash deposit surface of the equipment. Under the action of vibration, the ash deposit falls off.

Technical Specification

Vibration frequency 3 times/min

Vibration force 40-400 kN

Motor power 0.37 kW

Power Supply 380/220V

Shape size 690 x 250 x 1000 (long x wide x high mm)

Adjustment of Vibration Force

The vibratory force is 40 - 400kN, which can be adjusted according to the actual needs of the site. The method is as follows: loosen the bolt of the knockout block shown in the installation diagram, move the screw rod of the knockout block along the slide of the shell of the vibratory hammer, adjust the up and down position of the knockout block, and change the height of the hammer head, then the vibratory force is adjusted.

Equipment Installation Diagram